Vibration was applied from various directions to both oxygen-free copper (OFC) battery terminals—Model No. DTPL-1S and Model No. DTPS-1S—to verify and evaluate the reliability and durability of the products themselves.

| Test Location | Saitama Industrial Technology Center (SAITEC) |

|---|---|

| Test Standard | Based on JIS D 1601-1995 “Automobile Parts—Vibration Testing Methods” |

| Equipment Manufacturer | Emic Corporation |

|---|---|

| Model Number | F-26000BDH / LA26W |

| Maximum Excitation Force | Sine Wave: 26kN, Random: 20.8kNrms, Shock: 65kN |

| Excitation Frequency Range | No load: 3–2500 Hz; with horizontal exciter table: 3–2000 Hz; with vertical table: 3–500 Hz |

| Maximum Acceleration | Sine Wave: 963m/s2 |

| Maximum Velocity | 2.3m/s |

| Maximum Payload Capacity | 400 kgf (including specimens, fixtures, bolts, etc.) |

| Maximum Amplitude | 60mm p-p |

| Excitation Directions | Vertical and Horizontal Directions |

| Combined Test | -55℃ to 180℃ (Vertical Direction) |

| Available Test Types | Sine Vibration Test, Random Vibration Test, Shock Test |

| Vibration Test System Overview |  |

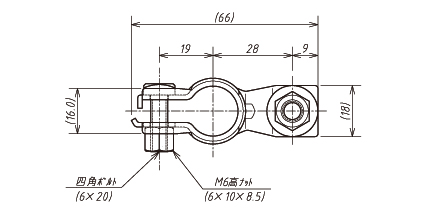

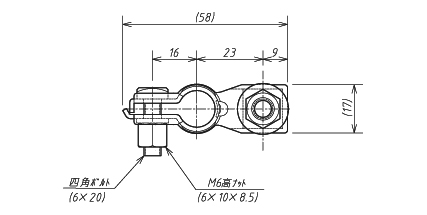

| Oxygen-Free Copper (OFC) Battery Terminals | |

|---|---|

| Model Number: DTPL-1S For Large Pole [L] (Type D Terminal) | Model Number: DTPS-1S For Small Pole [S] (Type B Terminal) |

|

|

(1) The vibration conditions of the components are classified according to the types of vehicles to which they are to be mounted, as follows.

Type 1: Mainly passenger vehicles

Type 2: Mainly buses

Type 3: Mainly trucks

Type 4: Mainly motorcycles

(2) The vibration conditions of the components are classified according to their installed condition, as follows.

Class A: When mounted on the vehicle body or on the suspension system above the spring, and subject to relatively low vibration

Class B: When mounted on the vehicle body or on the suspension system above the spring, and subject to relatively high vibration

Class C: When mounted on the engine and subject to relatively low vibration

Class D: When mounted below the suspension spring or on the engine, and subject to relatively high vibration

(3) Vibration Durability Test Method

The vibration durability test was conducted under the conditions shown in the table below.

| Stage | Frequency (Hz) | Vibration Acceleration (m/s²) | Test Time (Up/Down) | Test Time (Left/Right) | Test Time (Front/Back) |

|---|---|---|---|---|---|

| 90 | 33,67,or 133 | 90 (approximately 9.2G) | 4h | 2h | 2h |

Details above are excerpted from JIS D 1601-1995 “Automotive Parts Vibration Test Method”

(4) The test was conducted under the following conditions: (1) Type 3, (2) Class D, (3) Frequency of 67 Hz (equivalent to vibrations at approximately 2,000 rpm in a 4-cylinder engine). In addition, a 60 sq wire was connected to the test sample, and the test was performed under high-load conditions.

The focus of the test was to verify the vibration resistance of the bent section extending from the terminal body to the vertical M8 bolt.

A 60 sq wire was attached to the M8 vertical bolt. To increase the load on the bent section and assess its vibration reliability, external vibrations were intentionally applied—not only to evaluate the terminal itself but also to simulate high-load conditions.

The following video shows the test in progress based on the conditions described on the previous page (4). The vertical amplitude is approximately 1 mm, and the corresponding acceleration reaches 90 m/s² (approximately 9.2 G).

As described on the previous page (4), a vibration test was conducted in accordance with JIS D 1601-1995.As a result, neither the DTPL-1S nor the DTPS-1S exhibited any abnormalities—such as cracks or fractures—in the bent section of the terminal body.This test applied an extremely high vibration strength (9.2 G), far beyond what would typically occur in normal vehicle operation.Even under such severe conditions, the terminals demonstrated sufficient durability, confirming their high reliability.

| Test Specimen | Bent Section of Terminal Body | ||

|---|---|---|---|

| Cracks | Fractures | Breakage | |

| Model Number: DTPL-1S For Large Pole [L] (Type D Terminal) | None Observed | None Observed | None Observed |

| Model Number: DTPS-1S For Small Pole [S] (Type B Terminal) | None Observed | None Observed | None Observed |

*The illustrations are for reference only.

| This test is intended for use in standard passenger vehicles and does not guarantee the performance indicated above, nor does it assume any responsibility for it. |