Battery Terminals Preferred by Auto Electrical Repair Professionals

HERO Premium 24V Battery Interconnection Cable (Watarisen) for Heavy-Duty Vehicles

HERO Premium 24V Battery Interconnection Cable for Heavy-Duty Vehicles

DJ Series / DJ-RB Series

To ensure stable and efficient power delivery from the lead-acid batteries used in large vehicles such as trucks, buses, and construction machinery to various onboard electrical systems, Hero Electric employs terminals made from oxygen-free copper (OFC), a material with exceptional conductivity and a purity of 99.96%.The cable that connects the two batteries is the HERO Premium 24V Battery Interconnection Cable (Watarisen) — a product of two years of dedicated development, featuring a proprietary conductor structure and insulation material.Manufactured in Japan under strict quality standards set by Hero Electric, this cable offers unmatched performance and reliability, making it the ideal solution for demanding 24V battery systems in heavy-duty vehicles.

In recent years, engine and brake systems in heavy-duty vehicles have increasingly adopted electronic control technologies. As a result, the importance of stable low-voltage power—particularly for sensitive electronic components—has grown significantly.At the same time, these vehicles are constantly exposed to intense vibrations and harsh operating conditions, making it essential for components like the HERO Premium 24V Battery Interconnection Cable to deliver both high performance and durability in such demanding environments.

HERO Premium 24V Battery Interconnection Cable for heavy-duty vehicles delivers both high reliability and outstanding performance through a harmonious integration of materials: terminals made from highly conductive oxygen-free copper (OFC), and our original battery cable—both manufactured with the expert pressing techniques of master craftsmen.

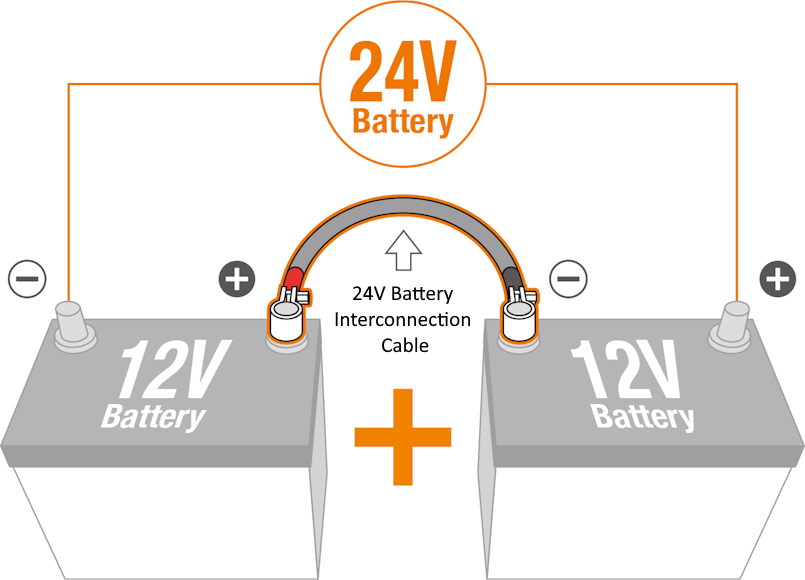

What Is the HERO Premium 24V Battery Interconnection Cable for Heavy-Duty Vehicles?

To provide sufficient cranking power for the larger starter motors required by heavy-duty diesel engines, two standard 12V batteries are connected in series to supply 24V—common practice in commercial vehicle electrical systems.

To connect the two batteries in series, a dedicated cable is required. At Hero Electric, we refer to this cable as the HERO Premium 24V Battery Interconnection Cable for Heavy-Duty Vehicles. It is also commonly known in the industry by various names such as “battery link cable,” “joint cable,” “intermediate battery cable,” or “midway cable.”

"MADE IN JAPAN" – a mark of trust and reliability

By integrating the extensive knowledge and specialized expertise that Hero Electric has cultivated over more than half a century into every aspect of the design phase—and manufacturing exclusively at domestic facilities under innovative technologies and a rigorous, comprehensive quality control system—we achieve exceptionally high precision and reliability in the products themselves.

To meet the supreme mission of achieving both "quality" and "durability" as professional-use products, all of our products are designed and developed entirely in-house.

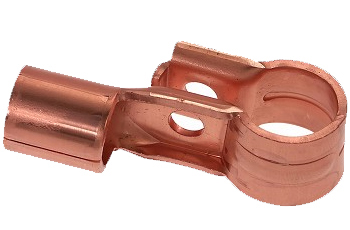

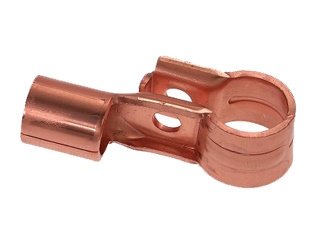

Uses Oxygen-Free Copper (OFC) with impurities removed to the utmost limit

For the first time in Japan's automotive aftermarket industry, we adopted Oxygen-Free Copper (OFC) as the core material for our battery terminal bodies. OFC is significantly purer and more conductive than standard copper, and is widely used in electronics and high-performance cables.

Images are for illustration purposes.

Not available for sale in bare (non-plated) form.

What is Oxygen-Free Copper (OFC) ?

High-purity copper with a purity of 99.96% or more

Oxygen-Free Copper is an exceptionally pure type of copper with minimal trace elements, impurities, and oxygen, resulting in a significantly higher purity compared to general copper.

High Electrical Conductivity

Oxygen-Free Copper has excellent electrical conductivity and is widely used in electronics, wiring, and conductors. Its high conductivity allows efficient transmission of electrical signals.

■Types, Grades, and Symbols of Materials Used in Oxygen-Free Copper (OFC) Battery Terminals

| Name | Type | Gradea) | Type Symbol | Key Features and Representative Applications (Reference Only) | |

|---|---|---|---|---|---|

| Alloy Number | Form | ||||

| Oxygen-Free Copper (OFC) | C1020 | Strip | Standard Grade | C1020Rb) | It has excellent electrical and thermal conductivity, ductility, and drawability. It also offers good weldability, corrosion resistance, and weather resistance. Even when heated to high temperatures in a reducing atmosphere, it does not risk hydrogen embrittlement. |

(Reference): Japanese Industrial Standard JIS H 3100:2018 Copper and Copper Alloy Plates and Strips

[Note]

b) For plates and strips used for electrical conduction, a "C" shall be added after the type symbols P, PS, R, or RS.

■ Chemical Composition of Oxygen-Free Copper (Alloy Number: C1020)

| Alloy Number | Chemical Composition (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cu | Pb | Fe | Sn | Zn | Al | Mn | Ni | P | Zr | |

| C 1020 | "Minimum 99.96%" | - | - | - | - | - | - | - | - | - |

(Reference): Japanese Industrial Standard JIS H 3100:2018 Copper and Copper Alloy Plates and Strips

■ Mechanical Properties of Materials Used in Oxygen-Free Copper (OFC) Battery Terminals

| Alloy Number | Grade | Product Symbol | Tensile Test | Bending test a) | Hardness test a) (for reference) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thickness Range mm |

Tensile Strengthb) N/mm2 |

Elongationb) % |

Thickness Range mm |

Bending Anglee) |

Inner Radiuse) |

Thickness Range mm |

Vickers Hardnessb) HV |

|||

| C1020 | ½H | C 1020 P-½Hd) C 1020 PS-½Hd) |

0.10~<0.15 | 235~315 | - | 0.10~2.0 | 180° | 1xThickness | 0.20~20 | 75~120e) |

| 0.15~<0.30 | ≧10 | |||||||||

| 0.30~20 | 245~315 | ≧15 | ||||||||

| C 1020 R-½Hd) C 1020 RS-½Hd) |

0.10~<0.15 | 235~315 | - | ≧0.20 | ||||||

| 0.15~<0.30 | ≧10 | |||||||||

| 0.30~4.0 | 245~315 | ≧15 | ≦4.0 | |||||||

(Reference): Japanese Industrial Standard JIS H 3100:2018 Copper and Copper Alloy Plates and Strips

[Notes]

a) Products that fall outside the specified thickness categories are not subject to bending or hardness tests.

b) Numerical values are rounded to the nearest whole number.

d) Also applicable to plates and strips used for electrical purposes.

e) Minimum test force is 1.961 N.

[Reference] Comparative Chart of Conductivity for Terminal Materials Used in 24V Battery Interconnection Cables for Repairs

| Comparative Materials | Oxygen-Free Copper (OFC) (Material used in our products) |

Lead |

|---|---|---|

| Material Conductivity (% IACS) | 101% | 9% |

*1. IACS refers to the International Annealed Copper Standard, which defines 100% IACS as the conductivity of annealed standard copper.

*2. The above values are general reference values and not absolute (guaranteed) values.

(*Note) Cu-Zn alloys are referred to as brass; the academic term is "黄銅" (ōdō).

(Reference): Osawa, Nao. "Illustrated Introduction to the Basics and Mechanisms of Copper." Shuwa System, 2010, p.106.

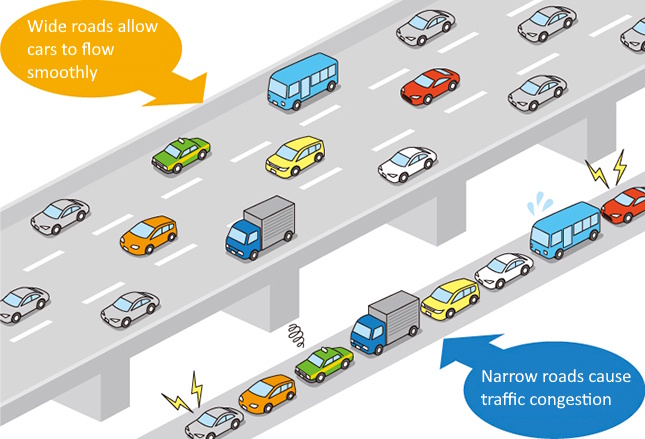

[Point] Easy-to-understand conductivity explained with illustrations

Conductivity can be compared to "road width," where smoother traffic flow represents higher efficiency.

Copper is a critical material for realizing a sustainable, decarbonized society through renewable energy and electric vehicles

■Renewable Energy Generation

Copper plays a vital role in renewable energy systems. Solar and wind power equipment requires large amounts of copper wiring. Copper's high conductivity and durability enhance the efficiency and sustainability of renewable energy generation.

■Electric Vehicles and Charging Infrastructure

Copper is an essential material in the production of electric vehicles. Motors, batteries, and charging infrastructure for electric vehicles require large amounts of copper. Its excellent conductivity and durability contribute to improved performance and efficiency in electric vehicles.

■Electronic Devices

Copper is also essential in electronics manufacturing. Copper wiring is used in computers, smartphones, and TVs. Its excellent heat conduction makes it suitable for use in cooling systems. As high-performance electronics become increasingly important in a decarbonized society, copper plays a crucial role in supporting this demand.

To prevent oxidation of the copper itself, tin plating is applied to the surface

Since oxygen-free copper (OFC) tends to lose its excellent conductivity due to surface oxidation when left uncoated, a tin plating with low contact resistance and long-term stability is applied as the surface treatment.Tin plating is widely used in electrical components. By forming a coating layer, it shields the material from exposure to air, thereby protecting the base metal while ensuring both reliable conductivity and corrosion resistance.

Developing products with a strong emphasis on unleashing maximum performance

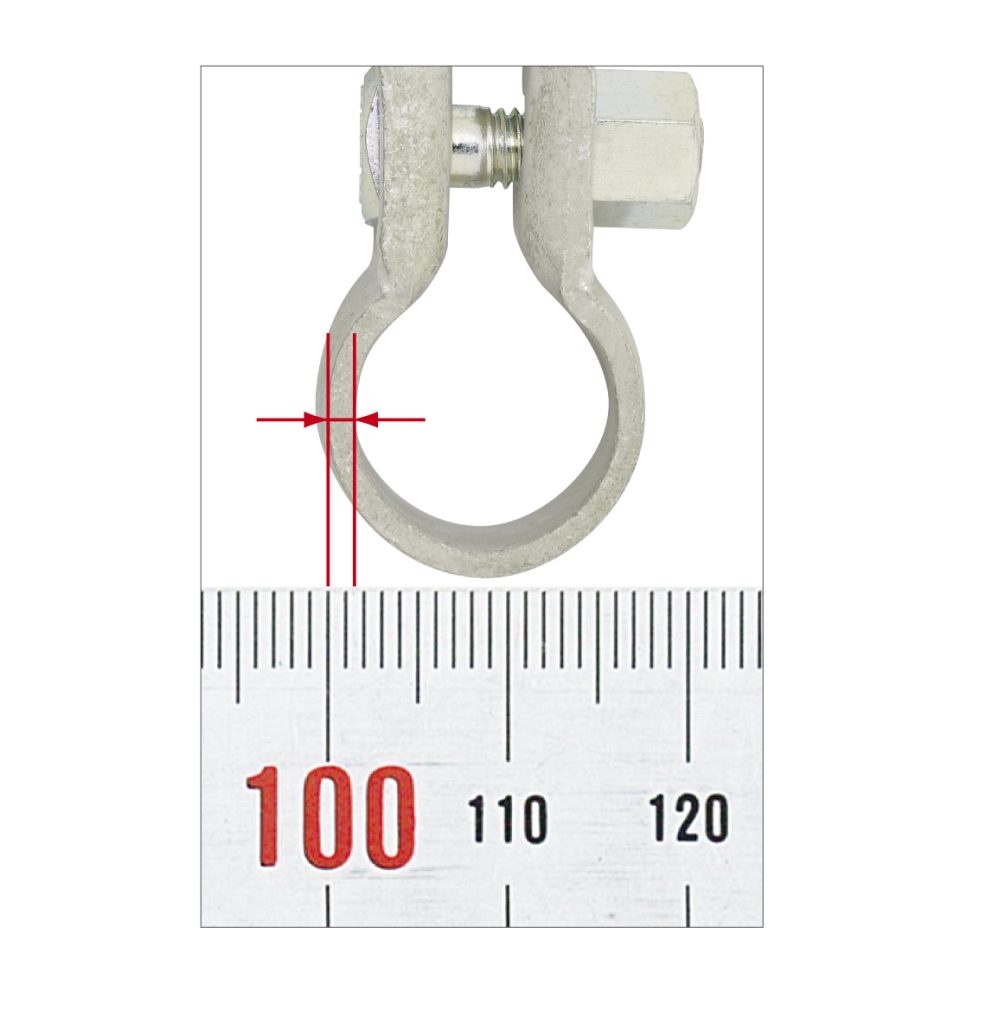

To ensure the highest priority of achieving both reliability and robustness as battery terminals under the extremely harsh conditions of automotive engine compartments, we have established key specifications that include thickened materials and a slitless structure—free from notches or cracks. From the design stage onward, our in-house product development integrates the technical expertise and know-how that Hero Electric has cultivated over the years.

| Development Concept | Background Behind the Development Concept |

|---|---|

| Enhanced Durability through Thicker Base Material |

|

| Slitless Structure |

|

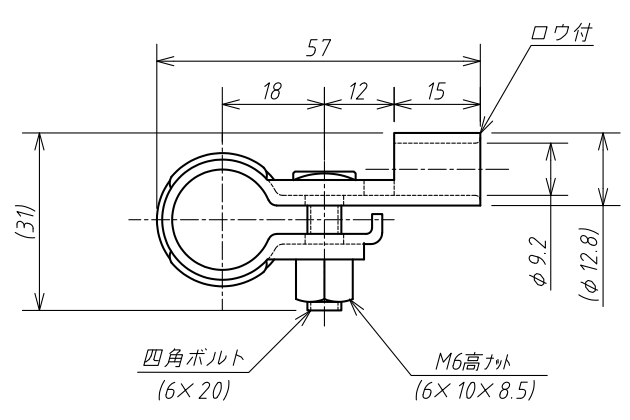

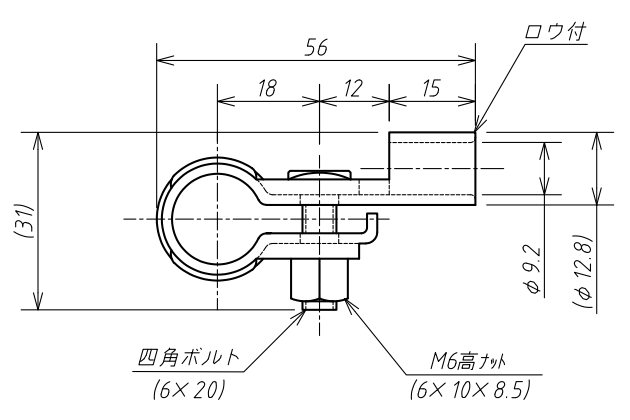

Thickness Validation of the HERO Premium 24V Battery Interconnection Cable for Heavy-Duty Vehicles

| 電線サイズ | 極性 | 肉厚 |

|---|---|---|

| 30.00cm2 | (+)極 | 1.8 mm (0.071 in) |

| (-)極 | 1.8 mm (0.071 in) | |

| 40.00cm2 | (+)極 | 1.8 mm (0.071 in) |

| (-)極 | 1.8 mm (0.071 in) | |

| 60.00cm2 | (+)極 | 2.0 mm (0.079 in) |

| (-)極 | 2.0 mm (0.079 in) |

(Dimensional tolerance: ±0.1 mm / ±0.039 in)

[Reference] Validation Based on Real-World Use Cases of Slit-Type Battery Terminals

Slits (cuts or cracks) can weaken the strength of objects or structures. When external force or load is applied to the slit, that area may become a point of weakness, increasing the likelihood of cracking or breakage.

Furthermore, Slit-type battery terminals that develop cracks due to vibrations from automobiles may cause unexpected vehicle issues, as increased contact resistance or poor connections can lead to voltage drops.

(*Note) The image shown is a standalone battery terminal with a slit.

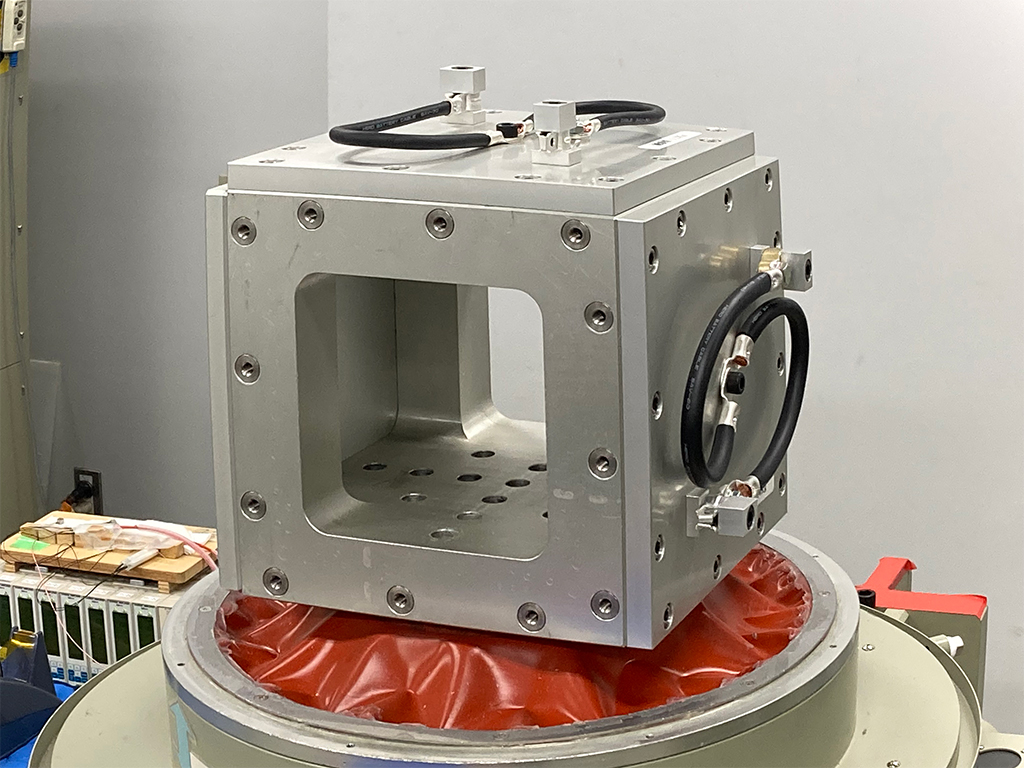

Verified by "Vibration Test" Based on JIS Standards (Test materials: DTPL and DTPS)

[Overview of Vibration Testing Equipment]

Actively promoting environmentally conscious manufacturing with consideration for issues such as climate change and biodiversity conservation

We place great importance on environmentally conscious manufacturing. As part of this commitment, over 30 years ago, Hero Electric took the lead in developing oxygen-free copper (OFC) battery terminals for automotive aftermarket use—completely free from hazardous substances such as lead, mercury, and cadmium—in compliance with the RoHS2 Directive. In line with RoHS2, Hero Electric will continue to actively contribute to global environmental preservation by providing compliant products and working toward a more sustainable future.

The RoHS2 (Restriction of Hazardous Substances Directive) is a directive issued by the European Union (EU) that restricts the use of specific hazardous substances in electrical and electronic equipment and their components. The goal of RoHS2 is to reduce harmful effects on both the environment and human health.

The ten substances restricted under the RoHS2 Directive are as follows:

- Lead

- Mercury

- Cadmium

- Hexavalent Chromium

- Polybrominated Biphenyls(PBBs)

- Polybrominated Diphenyl Ethers(PBDEs)

- Diisobutyl phthalate(DIBP)

- Dibutyl phthalate(DBP)

- Butyl benzyl phthalate(BBP)

- Bis(2-ethylhexyl) phthalate(DEHP)

These substances are recognized as harmful to the environment, particularly when they leak during waste disposal, potentially contaminating soil and water sources and negatively impacting ecosystems and human health.

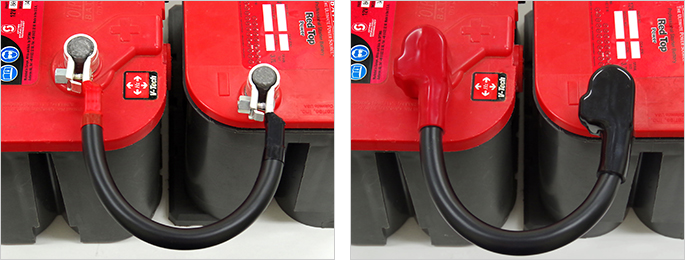

Quick Tips for Using the HERO Premium 24V Battery Interconnection Cable for Heavy-Duty Vehicles

Batteries installed in heavy-duty trucks and similar vehicles are subject to intense vibration during operation. As a result, they require components that offer exceptional performance and durability. In particular, the interconnection cable—linking the batteries—is a critical component whose reliability is paramount. Hero Electric’s 24V battery interconnection cable is built with the robust construction and reliability demanded by professionals, thanks to our proprietary pressing techniques perfected by skilled artisans.

Cross-Sectional Inspection of the Crimped Area on the HERO Premium 24V Battery Interconnection Cable for Heavy-Duty Vehicles

By securely and safely performing the installation (crimping) of battery terminals, and wires, the battery can fully deliver its intended performance.

[Reference] Tensile Strength Test of the Crimped Wire Section of the HERO Premium 24V Battery Interconnection Cable for Heavy-Duty Vehicles

■JIS Standard Name:

Crimp Terminals for Copper Wires

| Core Cross-Sectional Area (mm²) | JIS Standard Specified Tensile Strength Values for Crimped Sections (kgf) |

|---|---|

| 14.00 mm2 | 140.0 kgf |

| 22.00 mm2 | 180.0 kgf |

| 38.00 mm2 | 260.0 kgf |

| 60.00 mm2 | 330.0 kgf |

■ Product Specifications for the HERO Premium 24V Battery Interconnection Cable for Heavy-Duty Vehicles

| Parts number | Core Cross-Sectional Area (mm²) | JIS Standard Specified Tensile Strength Values for Crimped Sections (kgf) |

|---|---|---|

| DJ-33 | 30.00 mm2 | 278.3 kgf |

| DJ-34 | 40.00 mm2 | 295.4 kgf |

| DJ-36 | 60.00 mm2 | 459.0 kgf |

Testing Location: Hero Electric Co., Ltd. Quality Control Laboratory

The above values are for reference only and are not absolute or guaranteed values.

The HERO Premium 24V Battery Interconnection Cable for Heavy-Duty Vehicles uses open-type terminals. Since the JIS standard specifies closed-type terminals for copper wire crimping, the above performance data should be regarded as reference only.

HERO Original AV Soft Cable – Specially Developed through Hard-Won Expertise for Use in the HERO Premium 24V Battery Interconnection Cable for Heavy-Duty Vehicles

Guided by our corporate philosophy—"Contributing to a richer automotive life through original product development and an uncompromising pursuit of high-quality manufacturing"—Hero Electric took on a bold challenge that defied conventional industry wisdom: the use of oxygen-free copper as a terminal material for the HERO Premium 24V Battery Interconnection Cable for Heavy-Duty Vehicles. This is the story of our unwavering commitment to innovation and the relentless pursuit that made large-scale production a reality.

■ Laying the Groundwork for an Unprecedented Challenge

In 2004, driven by a deep commitment to environmental responsibility, Hero Electric made the bold decision to change the terminal material in our HERO Premium 24V Battery Interconnection Cable for Heavy-Duty Vehicles from lead to oxygen-free copper (OFC). This shift not only reflected our concern for the global environment, but also led to enhanced terminal performance.

However, the voices from the field—professionals who accept no compromise—soon reached us:

“We need cables that are easier to bend.”

“They stiffen too much in winter, especially in colder regions.”

Determined to answer these demands head-on, we embarked on the development of an entirely new battery cable that could meet the exacting standards of those who work on the front lines.

■ Joint Technical Development

Driven by an uncompromising pursuit of usability, we embarked on a two-year joint development project with a cable manufacturer.

Our goal: to create a battery cable that would outperform existing products in both flexibility and performance—even in harsh winter conditions and extreme cold.

But the path forward was anything but easy.

The process was marked by relentless trial and error, countless technical obstacles, and a determination that never wavered.

■ Innovative Achievement

After countless rounds of trial and error, we finally arrived at a breakthrough: a proprietary conductor structure and a carefully selected insulating material that led to the successful creation of the HERO Original Battery Cable.

With its distinctive flexibility and outstanding performance, it proved to be the ideal solution for cold-weather environments.

Used in the HERO Premium 24V Battery Interconnection Cable for Heavy-Duty Vehicles, this cable represents a groundbreaking achievement—combining environmental responsibility with exceptional usability across all conditions.

| Photo | Parts number | Standard specification | Materials | ||

|---|---|---|---|---|---|

| Conductor cross-sectional area (mm²) | Distance between poles (mm) | Electric Wire | Terminal | ||

|

DJ-23 | 30.00 mm² (approx. AWG #3 / 62.4 kcmil) | Length: 200 mm (approx. 7 7/8 in) | Soft AV Cable (HERO Original Specification) | Oxygen-free copper (OFC) |

| DJ-33 | 30.00 mm² (approx. AWG #3 / 62.4 kcmil) | Length: 300 mm (approx. 11 13/16 in) | |||

| DJ-34 | 40.00 mm² (approx. AWG #2 / 75.4 kcmil) | Length: 300 mm (approx. 11 13/16 in) | |||

| DJ-26 | 60.00 mm² (approx. AWG #1/0 / 117.2 kcmil) | Length: 200 mm (approx. 7 7/8 in) | |||

| DJ-36 | 60.00 mm² (approx. AWG #1/0 / 117.2 kcmil) | Length: 300 mm (approx. 11 13/16 in) | |||

|

DJ-34RB (with protective cover) |

40.00 mm² (approx. AWG #2 / 75.4 kcmil) | Length: 300 mm (approx. 11 13/16 in) | ||

| DJ-36RB (with protective cover) |

60.00 mm² (approx. AWG #1/0 / 117.2 kcmil) | Length: 300 mm (approx. 11 13/16 in) | |||

Watarisen (HERO Premium 24V Battery Interconnection Cable) FAQ

Is there a cable to connect two batteries in series for trucks and other vehicles?

Yes. Our HERO Premium 24V Battery Interconnection Cable (Watarisen), DJ Series, is designed for this purpose. Several types are available depending on wire size and length. Please refer to our product page and choose the model that best suits your application.

HERO Premium 24V Battery Interconnection Cable for Heavy-Duty Vehicles (Truck, Bus & Construction Machinery)| Hero Electric Co., Ltd.

https://hem.co.jp/info/category/battery_terminal/crossover

What is the HERO Premium 24V Battery Interconnection Cable (Watarisen)?

Trucks, buses, and other large vehicles are typically equipped with large diesel engines. The starter motor used to start these engines requires much more power than those in ordinary passenger cars. For this reason, large vehicles usually use two 12V batteries connected in series to provide 24V.

The cable used for this series connection is our HERO Premium 24V Battery Interconnection Cable, traditionally called Watarisen in Japan. It is also commonly referred to as a battery connecting cable, joint cable, interconnecting cable, or intermediate cable.

Is there a specific orientation when installing the HERO Premium 24V Battery Interconnection Cable (Watarisen)?

Yes. The HERO Premium 24V Battery Interconnection Cable (Watarisen) has both a positive terminal and a negative terminal. Since the terminal sizes are different, please make sure to check the poles of the battery before installation.

- The positive terminal has a “+” mark on the connector and a red heat-shrink tube on the cable.

- The negative terminal has a “–” mark on the connector and a black heat-shrink tube on the cable.

The HERO Premium 24V Battery Interconnection Cable (Watarisen) feels stiff and hard to bend. Why?

Hero Electric’s HERO Premium 24V Battery Interconnection Cable (Watarisen), designed for trucks, buses, and construction machinery, uses our original high-flexibility cable. Thanks to a specially designed flexible conductor, it remains easy to handle even in cold climates or winter conditions where wires typically become stiff.

| When installing the oxygen-free copper battery terminal,always check that there are no abnormalities on the post of the battery (lead-acid battery).Also, please make sure not to touch the battery fluid under any circumstances. |