A verification test was conducted to confirm that no leakage current occurs from the installed battery terminal cover when a high direct current is applied to the battery terminal.

| Test Location | Saitama Industrial Technology Center (SAITEC) |

|---|---|

| Test Method | Conductive copper foil was applied to the entire surface of the test sample, and a negative electrode was connected. Test voltage was applied. |

| Equipment Manufacturer | KIKUSUI ELECTRONICS CORP |

|---|---|

| Model Number | AC/DC Withstanding Voltage Tester: TOS5101 |

Test Voltage

| Applied Voltage | AC or DC 0–10kV |

|---|

AC Specification

| Maximum Rated Output (at Nominal Power Supply Voltage) | 500VA/10kV・50mA |

|---|---|

| Waveform | Commercial Power Supply Waveform |

| Voltage Fluctuation Rate (at Nominal Power Supply Voltage) | Within 15% (From Maximum Rated Load to No Load) |

| Switching | Zero-cross Switch Used |

DC Specification

| Maximum Rated Output (at Nominal Power Supply Voltage) | 50W/10kV・5mA |

|---|---|

| Ripple | Approx. 100Vp-p at 10kV No Load / Approx. 200Vp-p at Maximum Rated Output |

| Voltage Fluctuation Rate (at Nominal Power Supply Voltage) | Within 15% (From Maximum Rated Load to No Load) |

| Switching | Within 3% (From Maximum Rated Load to No Load) |

Output Voltmeter

| Analog | Scale | AC/DC Shared, 10kV Full Scale |

|---|---|---|

| Accuracy Class of Instrument Used | JIS Class 2.5 | |

| Measurement Accuracy | ±5% f.s | |

| AC Indicator | Average Response Measurement, RMS Calibrated Scale | |

| Digital | Full Scale | 5kV/10kV f.s |

| Measurement Accuracy | ±1.5% f.s | |

| AC Response | Average Response Measurement, RMS Display Calibration |

Ammeter

| Digital | Measurement Accuracy | ±(5% + 20μA) of Upper Limit Reference Value |

|---|---|---|

| AC Response | Average Response Measurement, RMS Display Calibration |

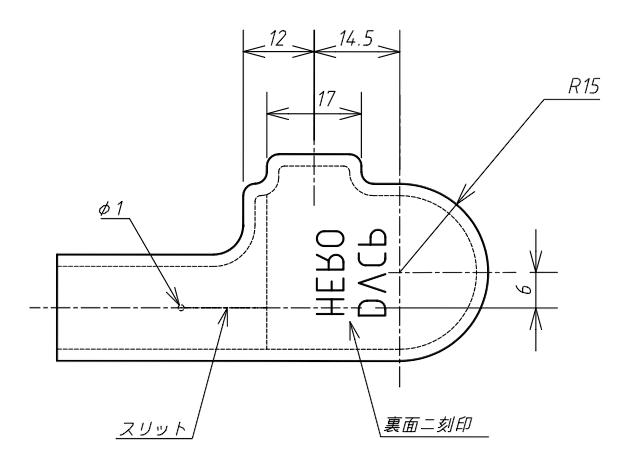

| Dedicated Terminal Cover for Oxygen-Free Copper (OFC) Battery Terminals |

|---|

| Parts No.: DVCP60 |

Material: PVC (Polyvinyl Chloride)

Wall Thickness: 2.0 mm (Dimensional Tolerance: ±0.5 mm) |

Although batteries installed in automobiles and similar vehicles typically operate at 12V or 24V, this test deliberately applied a high DC voltage of 1,000V to verify whether any leakage current would occur externally from the battery terminal cover.

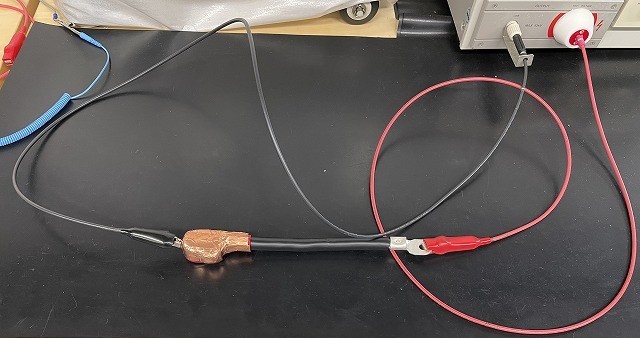

In this test method, the entire surface of the battery terminal cover (test sample) was covered with conductive copper foil tape. The cover was then mounted onto a battery terminal that had been crimped to a 60sq cable. A DC voltage of 1,000V (1kV) was applied for one minute between the cable and the copper foil on the cover to determine whether any leakage current would occur from the cover.

(Note: The applied voltage and duration in this test were determined independently by our company and are not based on any external standards.)

As shown in the photo on the right, even after DC 1.00kV was applied (left-side value on the tester display) for approximately one minute (right-side value), the leakage current remained at 0.00mA (center value), confirming that there was no external leakage current from the battery terminal cover. The target application time was one minute.

This test was conducted under voltage conditions far beyond those encountered in normal use. Since our similar battery terminal covers are made from the same material and have equivalent wall thickness, they can also be considered to possess sufficient dielectric strength.

| Dedicated Terminal Cover for Oxygen-Free Copper (OFC) Battery Terminals | Leakage Current Value |

|---|---|

| Test Voltage: DC 1,000V Test Duration: 1 Minute | No Abnormalities (0.00mA) |

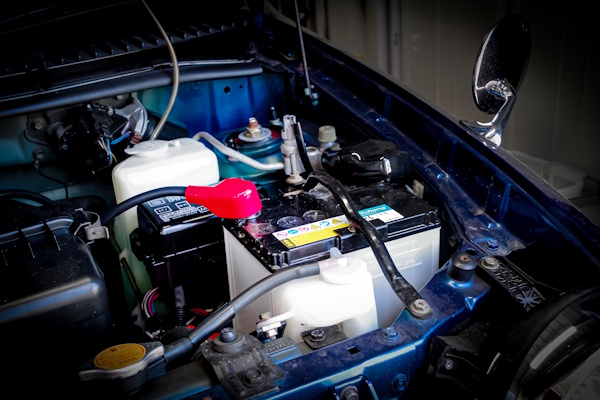

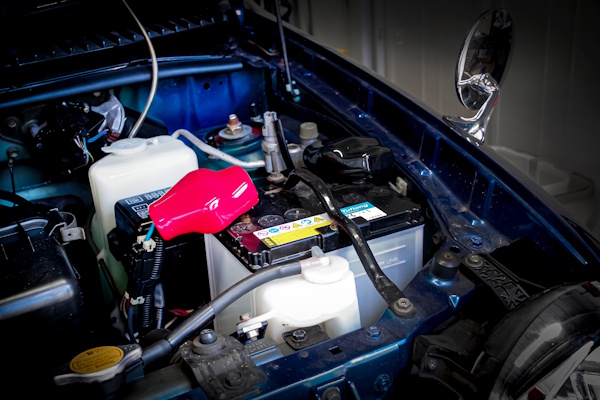

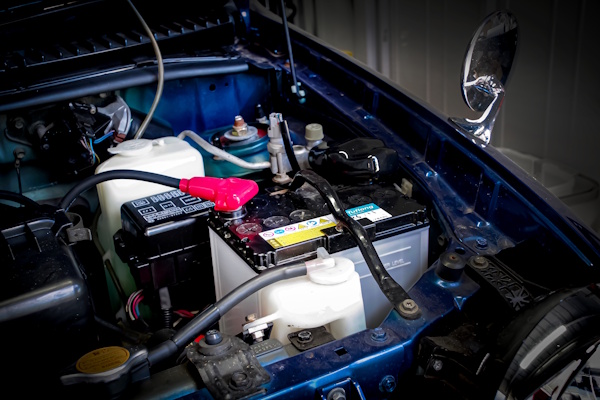

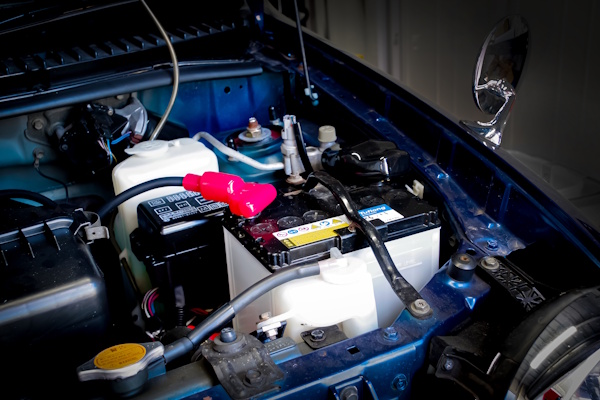

Installation Example

Vehicle Model

Daihatsu Mira Gino (Model: L700)

Products Installed on Vehicle

DVCP-60R

DVCP-22R

DVC-TXSR

DVC-DMR

DVC-50R

DVC-38R

DVC-60R

DVC-80R

| This test is conducted under the assumption of use in standard passenger vehicles, and the above results do not imply any performance guarantee or acceptance of responsibility. |

| This test was conducted based on our own internal standards, and the evaluation results cannot be applied directly to actual usage conditions. |

| Test contents are subject to change without notice. |