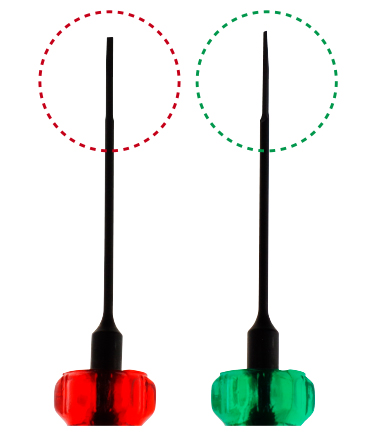

Terminal pin removal tool set

Terminal pin removal tool set FR-150

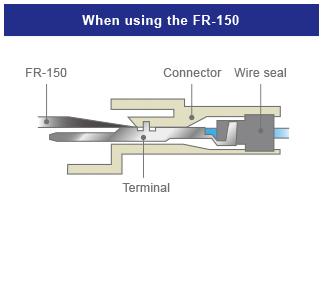

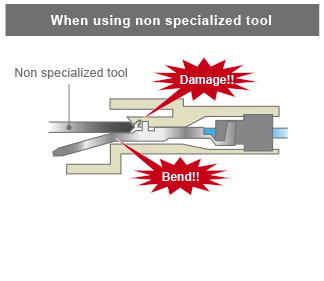

The FR-150 delivers excellent performance in response to the recent trend toward thinner automotive terminals.Its shaft is made from a material that balances wear resistance and elasticity, contributing to improved work efficiency.The uniquely shaped tip—designed based on years of expertise as a specialist manufacturer of automotive repair parts—enables smooth and reliable terminal extraction.Thanks to this thoughtful combination of material and design, the FR-150 has earned the strong trust of professional automotive technicians for over 25years.

Reliable "MADE IN JAPAN" Quality

“MADE IN JAPAN” isn’t just a label—it’s a reflection of the quality and reliability that define Japanese craftsmanship. From design to production, every step is carried out domestically to uphold these exacting standards. This professional-grade model embodies over 50 years of expertise in automotive electrical components. With more than 80,000 sets sold worldwide, it has contributed to improved terminal extraction efficiency in automobiles and other transport equipment for over a quarter-century.

Material Selection Focused on Professional Use

The shaft is made of carbon tool steel. Compared to the previously used nickel-chromium-molybdenum steel, the new material offers optimized hardness and elasticity, allowing force to be transferred more effectively to the tip when accessing terminal lances inside connectors—greatly improving ease of use. It also boasts superior wear resistance, ensuring durability over long-term use.

What is Carbon Tool Steel?

Carbon tool steel is an alloy primarily composed of iron with carbon (0.55–1.50%), manganese (0.10–0.50%), and silicon (0.10–0.35%). Widely used in mechanical and industrial applications, it is favored for tools and blades—such as drills, files, knives, and press dies—that require both strength and toughness.

[Reference Material] Comparison of Typical Components: Conventional vs. New Shaft Materials

| Steel type | Chemical composition (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| carbon | mangan | silicon | phosphorus | sulfur | nickel | chromium | molybdenum | |

| nickel-chromium-molybdenum steel | 0.12~0.50 | 0.30~1.20 | 0.15~0.35 | less than 0.030 |

less than 0.030 |

0.40~4.50 | 0.40~3.50 | 0.15~0.70 |

| carbon tool steel | 0.55~1.50 | 0.10~0.50 | 0.10~0.35 | less than 0.030 |

less than 0.030 |

- | - | - |

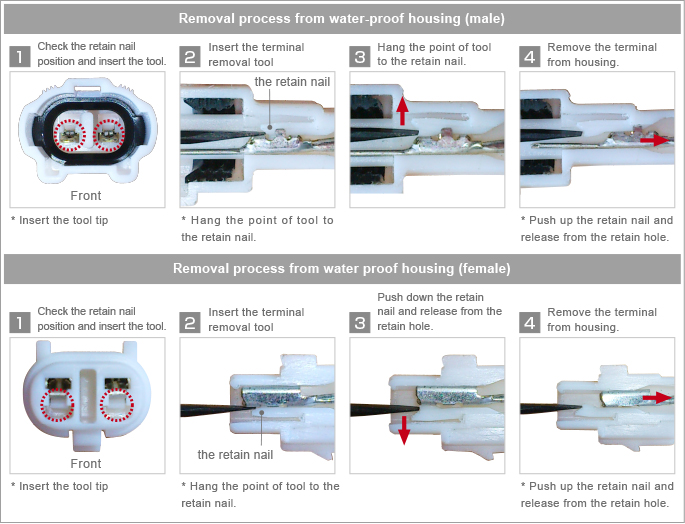

Precision Engineering Down to the Finest Detail

This tool was meticulously developed to ensure smooth and reliable extraction of terminals from both waterproof and non-waterproof connectors. Drawing on years of experience in the automotive aftermarket, we poured our full expertise into every aspect of the design—right down to the shape of the shaft tip—with an uncompromising attention to detail.

| Photo | Product | Parts number | Specifications |

|---|---|---|---|

|

110 Brass male terminal | B-6S | Applicable wire [mm2]0.50~1.25 [AWG]20~16 |

|

110 Brass male terminal | B-100S | Applicable wire [mm2]0.50~1.25 [AWG]20~16 |

|

Waterproof male terminal 060 (FRM) -series | FRM-101N | Applicable wire [mm2]0.50~0.85 [AWG]20~16(approx.) |

|

Waterproof male terminal 070 (FRA) -series | FRA-104N | Applicable wire [mm2]0.50~1.25 [AWG]20~16 |

|

Waterproof male terminal 070 (FRY) -series | FRY-101N | Applicable wire [mm2]0.50~0.85 [AWG]20~16(approx.) |

|

Waterproof male terminal 090 (FRS) -series | FRS-102N | Applicable wire [mm2]0.50~1.25 [AWG]20~16 |