The history of the Hero products

The 1960s

The Japan's high economic growth and doubled personal income caused full-scale motorization. The domestic number of automobiles owned reached the level of 10 million in 1967.

Founder of Hero Electric Kenji Seki recognized the crimping technique using terminals of AMP Incorporated, now TE Connectivity, a globally engaged U.S. connection device manufacturer, benefitting from having been a school friend of one of executives of its Japanese subsidiary, and commenced operation in Sotokanda, Chiyoda-ku, Tokyo, striving to create a new market of professional quality products in the automotive repair field where demand had been predicted to increase.

Commitment to professional use

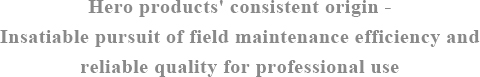

CRIMPER B-125 (Item # B-14), a crimping tool which combines reliability and robustness in itself and became synonymous with an automotive wiring repair tool at the dawn of Japan's motorization

Its excellent durability obtained from the stable structure that sufficiently endures many years of use in field maintenance and our commitment to Made in Japan from designing through manufacturing in order to meet requirements from professionals aiming at perfect maintenance has been highly regarded up to the present date after half a century.

Photo:

CRIMPER B-125 (Item # B-14), a crimping tool which has kept its professional quality for half a century (above)

Leaflets at the time of founding targeting domestic market (below left) and overseas market (below right)

Focus on materials and finishing treatments

Bullet terminals B-1 / B-2, which epitomize Hero Quality obtained from uncompromised commitment in every aspect of materials and finishing treatments in order to meet high level requirements from professionals

Specifically developed for automotive repair parts, our high performance bullet terminals only achievable through uncompromised commitment to Made in Japan and In-house Manufacturing to keep the quality enduring the harsh environment of vehicles boast of its long-term sales success of half a century mainly in the auto aftermarket both in Japan and abroad.

Reasons why Hero's bullet terminals are chosen

Photo:

Bullet terminals B-1 (above) and B-2 (below)

The 1970s

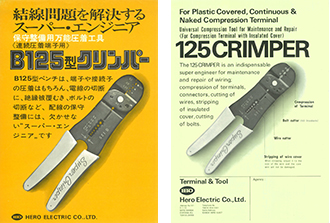

Basic items in a kit

AUTOMOTIVE TERMINAL KIT Type B, professional use, which is carried easily and makes it possible to troubleshoot wiring problems instantly through reliable crimping work, which was developed by challenging to the tradition of standard automotive wiring repair method: soldering. You can perform repairing work regardless of location condition and power supply availability.

Photo:

AUTOMOTIVE TERMINAL KIT Type B

Through the nation-wide sales network established by Hitachi Automobile Appliances Sales Co., Ltd. (now Astemo Aftermarket Japan, Ltd.), we have dedicated to spreading products mainly in the auto aftermarket and contributed to improving working efficiency of many professionals.

Photo:

A leaflet of a TERMINAL KIT (left)

A sales copy used on this advertising leaflet was Perfect Connections for Perfect Maintenance.

A leaflet of a TERMINAL BOX SET (right)

The Industry's first TERMINAL BOX was commercialized with a nickname of Wiring First Aid Kit

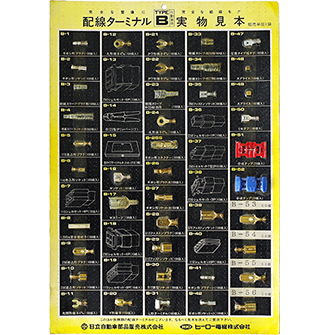

Photo:

AUTOMOTIVE WIRING TERMINAL TYPE-B REFERENCE GUIDE

A Must-Have guide sheet illustrated by pictures, which has been highly regarded by many professionals

Established a new category

Hero's first crimp type battery terminals DC series, which were newly commercialized in response to high demands from professionals aiming at perfect maintenance

We newly developed a crimp type battery terminal under the inherited basic principle of automotive repair wiring terminal: "Perfect Connections for Perfect Maintenance" which established a new category in automotive repair ahead of the industry.

Photo:

Battery terminals DC series

Combined cost benefit with usefulness

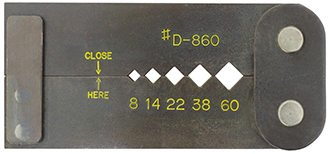

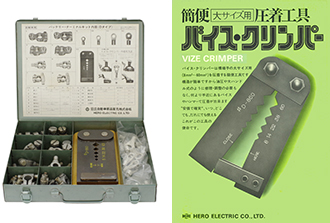

Crimping tool # D-860, which combined cost performance with improved field maintenance efficiency

Standard crimping devices for crimp type battery terminals or ring terminals had been expensive hydraulic crimping tools and heavyweight handle-type crimping tools. To replace these tools, we developed a Hero original crimping tool which combined cost benefit and workability. The industry's first automotive repair BATTERY TERMINAL KIT Type D was also newly commercialized.

Photo:

Crimping tool # D-860 (above)

BATTERY TERMINAL KIT Type D (left)

A leaflet at the time (right)

The 1980s

Industry's first material and original forming technology

Plate type Battery Terminal series which combine high conductivity given by its material and robustness enduring professional use in order to pursue further efficiency in power supply

In an age when materials for battery terminals were mainly zinc and zinc alloy, we independently developed the repair industry's first Plate type Battery Terminals, which was made using oxygen-free copper with an excellent conductivity, tackling a new proposition of improving conductivity we had received many requests from professionals.

Photo:

DCPL/DCPS series (above)

DOPL/DOPS series (middle)

DTPL/DTPS series (below)

To provide professional quality products, we have pursued a high performance and reliability of the product itself by committing to Made in Japan and In-house Manufacturing thoroughly from designing to manufacturing.

The 1990s

Standard field maintenance tool come from user point of view

Terminal pin removal tool FR-150, which makes it possible to remove various terminals with a single item come from the needs of improving field working efficiency.

One of our original products which was developed based on the experience cultivated for a quarter of a century as an automotive repair parts manufacturer made it possible to remove terminals more smoothly and securely by using so strong material that can be used in aircraft for its shaft and a unique tip form contrived from long years of experience.

Commercialization led by insights into future marketplace

Crimping tool for waterproof terminals FRC-100, which we have developed ahead of the industry driven by expectations of automotive waterproof connectors to be widespread

The fundamental concept of product development was the same with that of B-14: commitment to professional use. Although its development faced difficulty with an additional challenge of crimping waterproof terminals not seen in conventional concept, we overcome many hurdles and finally succeeded in commercializing the industry's first crimping tool for waterproof terminals.

Unrivalled overwhelming originality

Handy Crimper D-19N, which overturned the conventional crimping methods with an aim to improve efficiency in crimping work in tight spaces

One of Hero's original products born from unprecedented ideas unbound to conventional concepts of crimping tool by going back to the origin of Hero products' consistent principle: Improvement in field maintenance efficiency.

The 2000s

Realization of "I wish such a product existed"

Conversion battery terminal DXL and DXS series, which have generated new needs by putting together our original techniques and expertise in every aspect

To respond a latent needs in battery exchange, we developed this with all our heart passing on long-term in-house experience of designing and manufacturing of automotive repair parts for professional use and the DNA cultivated through the development of the Plate type Battery Terminal.

Further enhanced usability and quality

Crimping tool FRH-07, which makes a new history of Hero products passing on the blood of B-14, which had been the premier tool of professional use for half a century, and our waterproof-terminal crimping expertise cultivated through the development of FRC-100

In view of the increased use of finer wiring with electronization of vehicles and increased number of waterproof connectors, we developed FRH-07 with various expertise accumulated through the development of B-14 and FRC-100. Its tooth shape delicately designed with Hero's distinctive approach, which is unrivalled in crimping tools for professional use, realized a beautiful and secure crimping finish of terminals.

The 2010s

Devised products lead many variations

Handy Crimper D-20N, which was born as a new model derived from D-19N in response to high demands for commercialization from the market

One of Hero's original products which reflected the terminal crimping technique and a property of tensile strength made it possible to crimp thick wires (38mm2 to 60mm2) to respond many requests we had received.

Promoter of pioneering a new field

The industry's first waterproof terminal kit FR KIT, which contains waterproof terminals and Hero original tools, passing on the blood of AUTOMOTIVE TERMINAL KIT Type B,

The industry's first kit specified for waterproof terminals meeting requirements from professionals, which contains various selected waterproof terminals and waterproof housings frequently used in field maintenance, including a crimping tool for waterproof terminals FRH-07 and terminal removal tools FR-150, which uses nickel-chrome-molybdenum steel, one of strongest alloy metals with excellent mechanical property that is used for aircraft parts, as its shaft material, aims to generate new demands

In all ages, a picture is worth a thousand words

WIRING PARTS SAMPLE, a sample board which was modernized the WIRING TERMINAL REFERENCE GUIDE born in response to the needs of the times and achieved a large population for half a century

Based on the industry's first AUTOMOTIVE WIRING TERMINAL TYPE-B REFERENCE GUIDE, which had been highly regarded as a must-have item of maintenance factories to improve automotive wiring repair work, selected representative products (49 items) were contained in a modernized reprinted version.

The 2020s

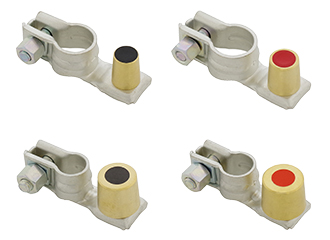

A coveted masterpiece for enthusiasts: oxygen-free copper (OFC) with 24K gold plating

To meet the evolving and increasingly diverse demands of the times, Hero Electric introduced a new 24K gold-plated variant as a next-generation evolution of our trusted Oxygen-Free Copper (OFC) battery terminals.

Made from ultra-high-purity oxygen-free copper (OFC) with a copper content of 99.96% or higher and virtually no oxides, this product delivers outstanding electrical conductivity. The surface is finished with 24K gold plating—not just for visual appeal, but also for its superior corrosion resistance and excellent conductivity. A truly coveted masterpiece for discerning car audio enthusiasts.

Through the fusion of oxygen-free copper (OFC) and proprietary intellectual property, we have established a new paradigm of value that sets our battery terminals apart

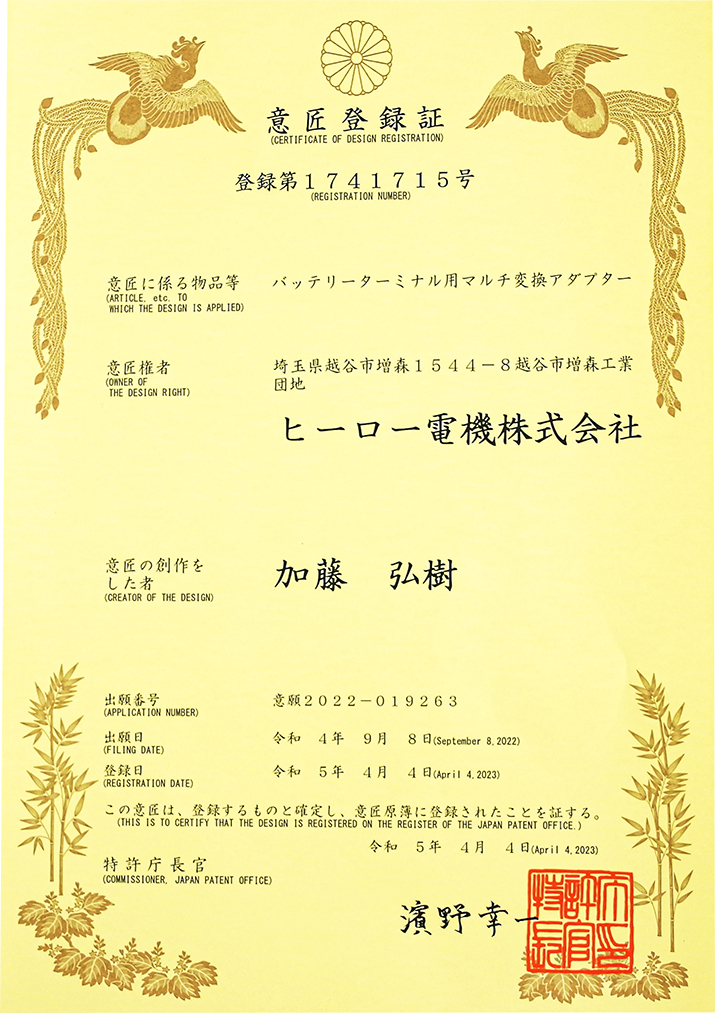

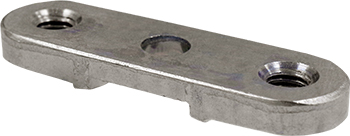

Building upon our oxygen-free copper (OFC) bolt-type battery terminal and over half a century of technical expertise developed by Hero Electric, we created a multi-type terminal that integrates our proprietary surface plating—IONICOAT/SK—an outstanding composite alloy coating that delivers corrosion resistance equivalent to SUS304 stainless steel. The result is a high-performance OFC terminal engineered for durability and precision.

Building upon the foundational concept of our cast-brass multi-type battery terminal—originally developed by breaking free from all conventional assumptions—we took the design further by incorporating oxygen-free copper (OFC) even into the plate section, which had long been considered unfeasible for mass production. As the first model in the Hero Electric original terminal series to receive a design patent, this product stands as a battery terminal truly positioned to lead the next generation.

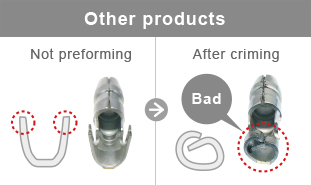

Hero Electric's bullet terminals B-1/B-2

Reason why these are chosen by professionals for half a century

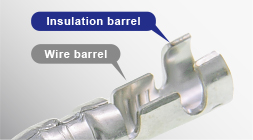

The insulation barrel of our bullet terminals is applied a treatment called pre-form. The most important point when crimping the insulation barrel is to press the wire insulation equally. The form of our insulation barrel treated the pre-form allows the barrel to be set steadily on teeth of the tool to form a good crimped shape as applied pressure.

Products without pre-form are likely to cause crimp defects when crimped abruptly. Therefore, such products require a trick before crimping such as thinning the barrel width or bending the barrel

tips a little bit, resulting in additional processes.