Battery Terminals Preferred by Auto Electrical Repair Professionals

Oxygen-Free Copper (OFC) Battery Terminals – Ionis-Coat / SK Specifications

Oxygen-Free Copper (OFC) Battery Terminals – Bolt Type

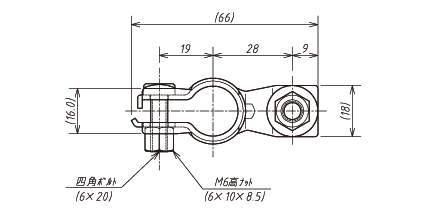

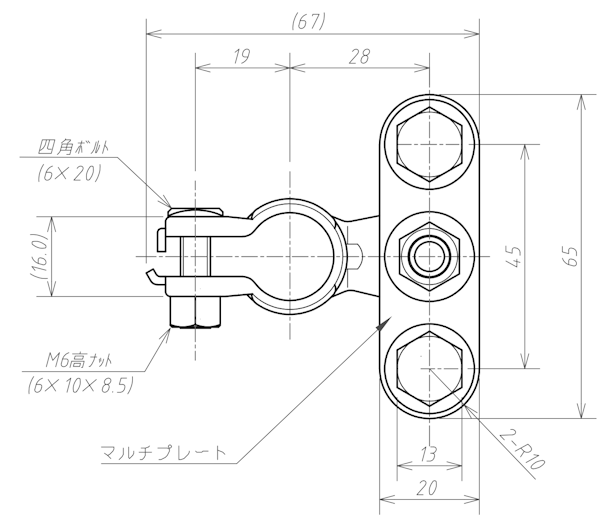

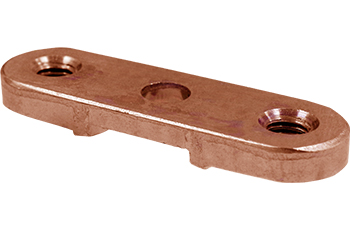

DTPL-SK Series / DTPS-SK Series

Oxygen-Free Copper (OFC) Battery Terminals – Multi Type

DMPL Series / DMPS-SK Series

Note: The bolt-type Ionis Coat / SK specification is scheduled for future release.

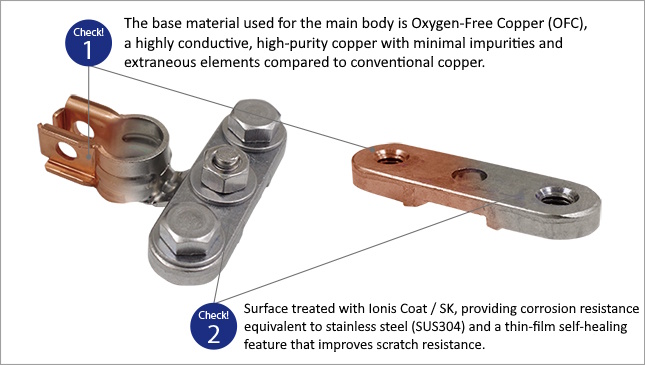

To ensure the stable and efficient transmission of power from lead-acid batteries used in automobiles and other vehicles to various electrical components, these battery terminals are made from the highest-grade oxygen-free copper (OFC), which boasts a purity of 99.96% or higher and contains minimal impurities and additives. OFC is widely recognized for its exceptional electrical conductivity. The terminals also feature a superior surface treatment that offers corrosion resistance equivalent to stainless steel (SUS304). Manufactured in Japan to meet Hero Electric’s rigorous quality standards, they deliver unparalleled performance and reliability.

In 1988, Hero Electric became the first in the industry to adopt highly conductive oxygen-free copper (OFC) as the base material for automotive replacement battery terminals—pioneering a new standard in the aftermarket. Since then, we have consistently dedicated ourselves to improving power transmission efficiency. With over 30 years of proven performance in Japan’s automotive aftermarket, our terminals are widely acclaimed for meeting the demanding expectations of frontline professionals and continue to earn their trust to this day.

As modern vehicles demand increasingly greater electrical power than in the past, the lead-acid batteries that supply this energy are trending toward being more compact and higher in performance. In response to these evolving needs, Hero Electric remains committed to pursuing exceptional “quality” and “durability” to ensure that our products consistently deliver reliable performance under all conditions.

"MADE IN JAPAN" – a mark of trust and reliability

By integrating the extensive knowledge and specialized expertise that Hero Electric has cultivated over more than half a century into every aspect of the design phase—and manufacturing exclusively at domestic facilities under innovative technologies and a rigorous, comprehensive quality control system—we achieve exceptionally high precision and reliability in the products themselves.

To meet the supreme mission of achieving both "quality" and "durability" as professional-use products, all of our products are designed and developed entirely in-house.

Uses Oxygen-Free Copper (OFC) with impurities removed to the utmost limit

For the first time in Japan's automotive aftermarket industry, we adopted Oxygen-Free Copper (OFC) as the core material for our battery terminal bodies. OFC is significantly purer and more conductive than standard copper, and is widely used in electronics and high-performance cables.

Images are for illustration purposes.

Not available for sale in bare (non-plated) form.

What is Oxygen-Free Copper (OFC) ?

High-purity copper with a purity of 99.96% or more

Oxygen-Free Copper is an exceptionally pure type of copper with minimal trace elements, impurities, and oxygen, resulting in a significantly higher purity compared to general copper.

High Electrical Conductivity

Oxygen-Free Copper has excellent electrical conductivity and is widely used in electronics, wiring, and conductors. Its high conductivity allows efficient transmission of electrical signals.

■Types, Grades, and Symbols of Materials Used in Oxygen-Free Copper (OFC) Battery Terminals

| Name | Type | Gradea) | Type Symbol | Key Features and Representative Applications (Reference Only) | |

|---|---|---|---|---|---|

| Alloy Number | Form | ||||

| Oxygen-Free Copper (OFC) | C1020 | Strip | Standard Grade | C1020Rb) | It has excellent electrical and thermal conductivity, ductility, and drawability. It also offers good weldability, corrosion resistance, and weather resistance. Even when heated to high temperatures in a reducing atmosphere, it does not risk hydrogen embrittlement. |

(Reference): Japanese Industrial Standard JIS H 3100:2018 Copper and Copper Alloy Plates and Strips

[Note]

b) For plates and strips used for electrical conduction, a "C" shall be added after the type symbols P, PS, R, or RS.

■ Chemical Composition of Oxygen-Free Copper (Alloy Number: C1020)

| Alloy Number | Chemical Composition (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Cu | Pb | Fe | Sn | Zn | Al | Mn | Ni | P | Zr | |

| C 1020 | "Minimum 99.96%" | - | - | - | - | - | - | - | - | - |

(Reference): Japanese Industrial Standard JIS H 3100:2018 Copper and Copper Alloy Plates and Strips

■ Mechanical Properties of Materials Used in Oxygen-Free Copper (OFC) Battery Terminals

| Alloy Number | Grade | Product Symbol | Tensile Test | Bending test a) | Hardness test a) (for reference) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thickness Range mm |

Tensile Strengthb) N/mm2 |

Elongationb) % |

Thickness Range mm |

Bending Anglee) |

Inner Radiuse) |

Thickness Range mm |

Vickers Hardnessb) HV |

|||

| C1020 | ½H | C 1020 P-½Hd) C 1020 PS-½Hd) |

0.10~<0.15 | 235~315 | - | 0.10~2.0 | 180° | 1xThickness | 0.20~20 | 75~120e) |

| 0.15~<0.30 | ≧10 | |||||||||

| 0.30~20 | 245~315 | ≧15 | ||||||||

| C 1020 R-½Hd) C 1020 RS-½Hd) |

0.10~<0.15 | 235~315 | - | ≧0.20 | ||||||

| 0.15~<0.30 | ≧10 | |||||||||

| 0.30~4.0 | 245~315 | ≧15 | ≦4.0 | |||||||

(Reference): Japanese Industrial Standard JIS H 3100:2018 Copper and Copper Alloy Plates and Strips

[Notes]

a) Products that fall outside the specified thickness categories are not subject to bending or hardness tests.

b) Numerical values are rounded to the nearest whole number.

d) Also applicable to plates and strips used for electrical purposes.

e) Minimum test force is 1.961 N.

[Reference] Comparative Table of Conductivity of Various Materials Commonly Used for Battery Terminals

| Comparative Materials | Oxygen-Free Copper (OFC) (Material used in our products) |

Brass | Zinc Alloy Die-Cast | Lead |

|---|---|---|---|---|

| Material Conductivity (% IACS) | 101% | 28% | 26% | 9% |

*1. IACS refers to the International Annealed Copper Standard, which defines 100% IACS as the conductivity of annealed standard copper.

*2. The above values are general reference values and not absolute (guaranteed) values.

(*Note) Cu-Zn alloys are referred to as brass; the academic term is "黄銅" (ōdō).

(Reference): Osawa, Nao. "Illustrated Introduction to the Basics and Mechanisms of Copper." Shuwa System, 2010, p.106.

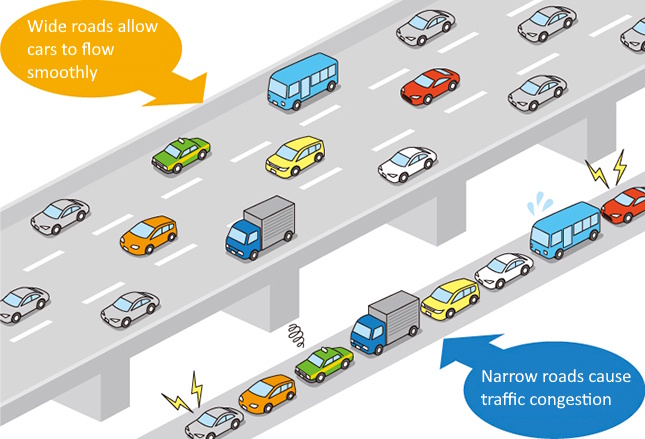

[Point] Easy-to-understand conductivity explained with illustrations

Conductivity can be compared to "road width," where smoother traffic flow represents higher efficiency.

Copper is a critical material for realizing a sustainable, decarbonized society through renewable energy and electric vehicles

■Renewable Energy Generation

Copper plays a vital role in renewable energy systems. Solar and wind power equipment requires large amounts of copper wiring. Copper's high conductivity and durability enhance the efficiency and sustainability of renewable energy generation.

■Electric Vehicles and Charging Infrastructure

Copper is an essential material in the production of electric vehicles. Motors, batteries, and charging infrastructure for electric vehicles require large amounts of copper. Its excellent conductivity and durability contribute to improved performance and efficiency in electric vehicles.

■Electronic Devices

Copper is also essential in electronics manufacturing. Copper wiring is used in computers, smartphones, and TVs. Its excellent heat conduction makes it suitable for use in cooling systems. As high-performance electronics become increasingly important in a decarbonized society, copper plays a crucial role in supporting this demand.

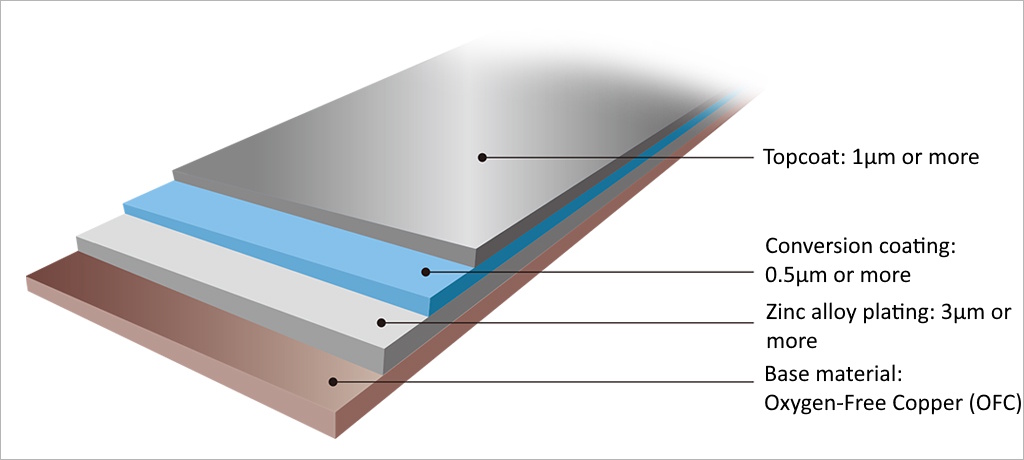

Surface coated with "Ionis Coat / SK" offering corrosion resistance equivalent to stainless steel (SUS304)

The surface of the oxygen-free copper (OFC) is treated with Ionis Coat / SK, a highly corrosion-resistant composite alloy plating.This advanced coating offers corrosion resistance equivalent to that of stainless steel (SUS304), ensuring excellent protection against rust.In addition, it features a thin-film structure with self-healing properties, providing enhanced resistance to surface scratches.

What is Ionis Coat / SK?

Ionis Coat / SK is an advanced next-generation surface treatment offering excellent corrosion resistance, protection against galvanic corrosion, and self-healing capabilities.

A trivalent chromate process is applied to a zinc-nickel alloy base, followed by a topcoat containing a water-soluble silica-based rust-proof coating. Even if the plating layer is scratched, the topcoat dissolves to cover the damaged area, providing self-healing protection.

Ionis Coat / SK is now widely used across a variety of applications.One prominent example is its adoption as a surface treatment for fastening screws used in the installation of mega solar panels, which are exposed to harsh environmental conditions over long periods.

*Note: Deep scratches that physically peel off the topcoat or cut through it—such as those caused by tools or sharp objects—will not self-heal.

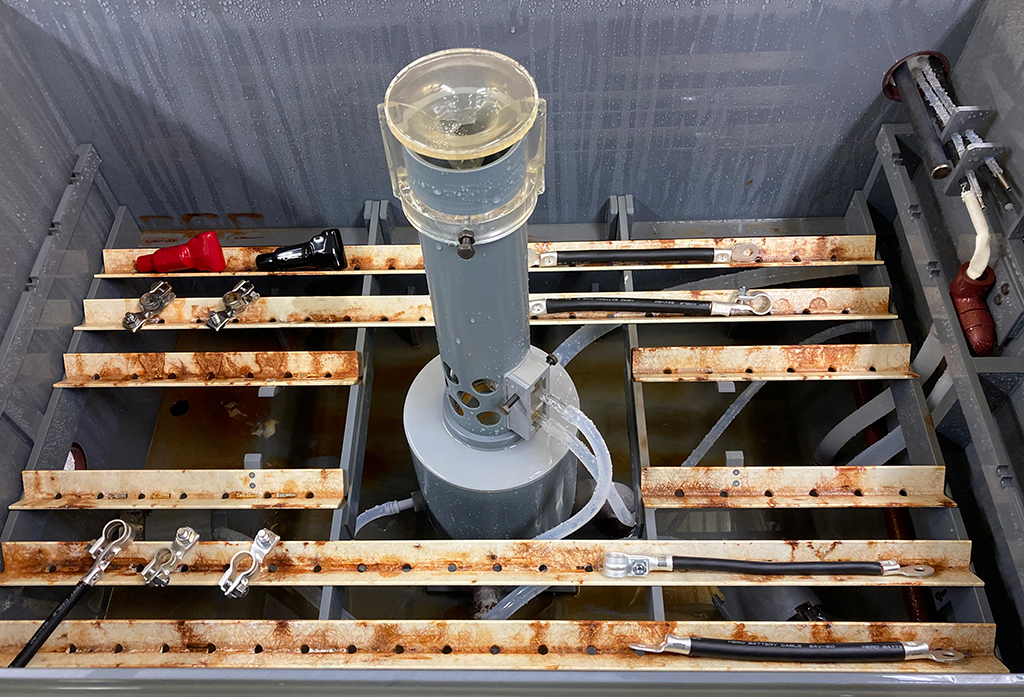

Verification conducted using our proprietary composite cycle test (See details: Test materials – DTPL-1S and DTPL-1SK)

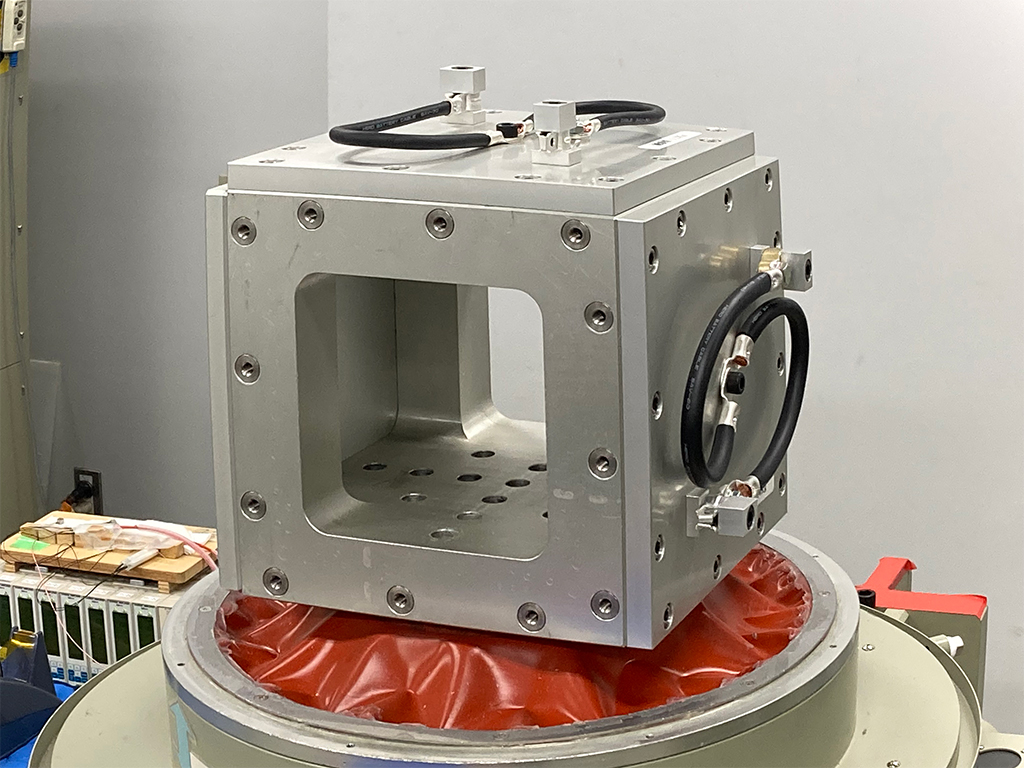

[General View of the Composite Cycle Test Apparatus]

Condition during testing

Developing products with a strong emphasis on unleashing maximum performance

To ensure the highest priority of achieving both reliability and robustness as battery terminals under the extremely harsh conditions of automotive engine compartments, we have established key specifications that include thickened materials and a slitless structure—free from notches or cracks. From the design stage onward, our in-house product development integrates the technical expertise and know-how that Hero Electric has cultivated over the years.

| Development Concept | Background Behind the Development Concept |

|---|---|

| Enhanced Durability through Thicker Base Material |

|

| Slitless Structure |

|

Thickness Verification of Oxygen-Free Copper (OFC) Battery Terminals

| Products | Plate Thickness | |

|---|---|---|

| Bolt-Type Model | DTPL Series | 1.8 mm (0.071 in) |

| DTPS Series | 1.5 mm (0.059 in) | |

| Multi-Type Model | DMPL Series | 1.8 mm (0.071 in) |

| DMPS Series | 1.5 mm (0.059 in) | |

(Dimensional tolerance: ±0.1 mm / ±0.004 in)

[Reference] Validation Based on Real-World Use Cases of Slit-Type Battery Terminals

Slits (cuts or cracks) can weaken the strength of objects or structures. When external force or load is applied to the slit, that area may become a point of weakness, increasing the likelihood of cracking or breakage.

Furthermore, Slit-type battery terminals that develop cracks due to vibrations from automobiles may cause unexpected vehicle issues, as increased contact resistance or poor connections can lead to voltage drops.

Verified by "Vibration Test" Based on JIS Standards (Test materials: DTPL and DTPS)

[Overview of Vibration Testing Equipment]

Actively promoting environmentally conscious manufacturing with consideration for issues such as climate change and biodiversity conservation

We place great importance on environmentally conscious manufacturing. As part of this commitment, over 30 years ago, Hero Electric took the lead in developing oxygen-free copper (OFC) battery terminals for automotive aftermarket use—completely free from hazardous substances such as lead, mercury, and cadmium—in compliance with the RoHS2 Directive. In line with RoHS2, Hero Electric will continue to actively contribute to global environmental preservation by providing compliant products and working toward a more sustainable future.

The RoHS2 (Restriction of Hazardous Substances Directive) is a directive issued by the European Union (EU) that restricts the use of specific hazardous substances in electrical and electronic equipment and their components. The goal of RoHS2 is to reduce harmful effects on both the environment and human health.

The ten substances restricted under the RoHS2 Directive are as follows:

- Lead

- Mercury

- Cadmium

- Hexavalent Chromium

- Polybrominated Biphenyls(PBBs)

- Polybrominated Diphenyl Ethers(PBDEs)

- Diisobutyl phthalate(DIBP)

- Dibutyl phthalate(DBP)

- Butyl benzyl phthalate(BBP)

- Bis(2-ethylhexyl) phthalate(DEHP)

These substances are recognized as harmful to the environment, particularly when they leak during waste disposal, potentially contaminating soil and water sources and negatively impacting ecosystems and human health.

Hero Electric's Exclusively Designed Battery Terminal Cover — Where Function Meets Form

To improve usability, HERO Electric has expanded its original battery terminal cover series by introducing dedicated covers designed to fit both types of oxygen-free copper (OFC) battery terminals—standard and conversion models. These covers have been developed using HERO’s proprietary technologies and know-how, refined over many years, while also pursuing a sophisticated and functional design. In order to ensure high product reliability, domestic production is maintained without compromise. Like other products in the lineup, the covers feature increased wall thickness for enhanced durability and safety.

Cover for Oxygen-Free Copper (OFC) Battery Terminal – Bolt Type (Compatible with DTPL and DXL models)

Cover for Oxygen-Free Copper (OFC) Battery Terminal – Bolt Type (Compatible with DTPS and DXS models)

Verification Results of Leakage Current Testing Based on Our In-House Standards (Test Material: DVCP60)

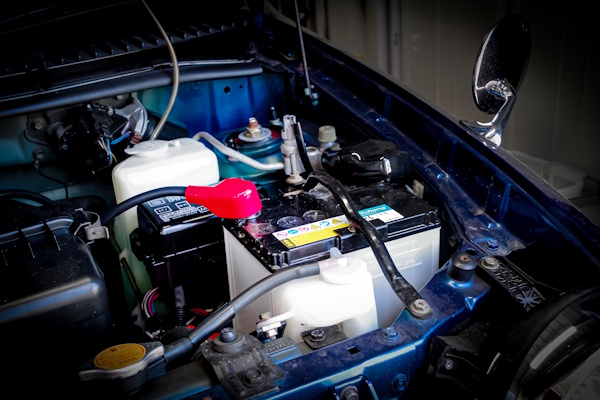

[On-Vehicle Installation Example of Dedicated Cover for Oxygen-Free Copper (OFC) Battery Terminals]

State During Testing

One-Point Advice for Using Oxygen-Free Copper (OFC) Battery Terminals

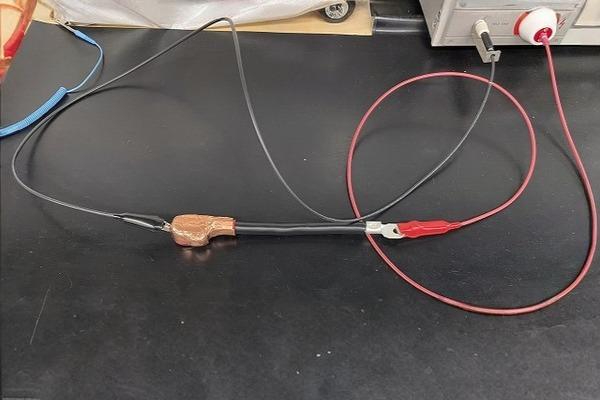

At Hero Electric, we have consistently upheld our core philosophy of “Perfect Wiring for Perfect Maintenance” since our founding. Based on this principle, we recommend the crimping method for connecting wires and terminals, as it ensures secure and stable contact over long periods of use.

By using the Hero Original Handy Crimper "D-19N" and "D-20N," the tensile strength of the crimped area satisfies the standard defined by the Society of Automotive Engineers of Japan (JASO), specifically "JASO D616: Minimum Tensile Strength of Conductor Crimped Parts."JASO D616 is a specification used in the automotive industry to ensure the quality and safety of conductor crimped connections.Meeting this standard indicates that the crimped area possesses the required tensile strength and delivers a highly reliable electrical connection.

Cross-Sectional Analysis of Crimped Area for Round Terminal (Product No. DR14-8)

Both D-19N and D-20N meet the JASO standard for minimum tensile strength of conductor crimped parts.

By securely and safely performing the installation (crimping) of battery terminals, ring terminals, and wires, the battery can fully deliver its intended performance.

Vibrations generated by a car's engine and during driving can affect the connection between battery terminals and wires. Loose connections may cause contact failure, resulting in voltage drops, battery drain, or even malfunctions in electronic devices. Therefore, a secure connection between the wire and terminal is extremely important.

[Reference] JASO Standard: Industrial standards established by the Society of Automotive Engineers of Japan (JSAE)

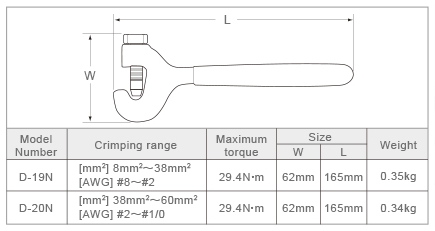

Product Specifications for Crimping Tools

Hero Original Handy Crimper

| Photo | Type | Parts number | Standard specification | ||||

|---|---|---|---|---|---|---|---|

| Pole size | Application | Polarity | Materials | Surface finish | |||

|

Bolt-Type | DTPL-1SK | For Large Pole [L] (Type D Terminal) | Vertical Bolt Section: M8 | + | Oxygen-Free Copper (OFC) | Ionis Coating/SK |

| DTPL-2SK | - | ||||||

| DTPS-1SK | For Small Pole [S] (Type B Terminal) | + | |||||

| DTPS-2SK | - | ||||||

|

Multi-Type | DMPL-1 | For Large Pole [L] (Type D Terminal) | Vertical Bolt Section: M8 (All 3 Bolts Identical) | + | ||

| DMPL-2 | - | ||||||

| DMPS-1 | For Small Pole [S] (Type B Terminal) | + | |||||

| DMPS-2 | - | ||||||

Note: The bolt-type Ionis Coat / SK specification is scheduled for future release.

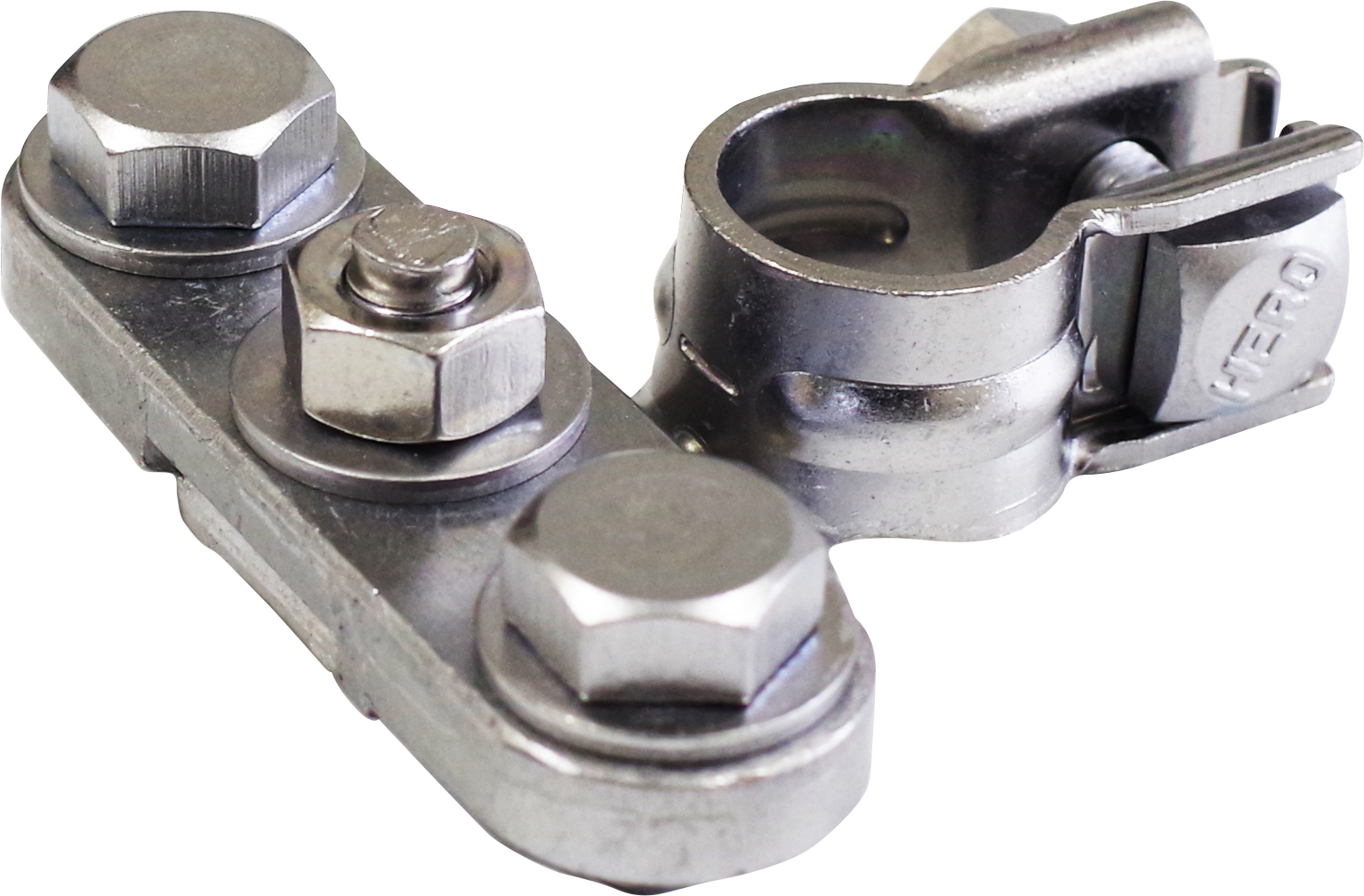

Installation Example

Vehicle Model

Daihatsu Mira Gino (Model: L700)

Replacement Products

Oxygen-Free Copper (OFC) Battery Terminal

(Parts No.: DTPS-2S)

Step 1 Prepare Necessary Components Including Battery Terminals

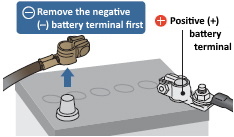

Step 2 Remove Battery Terminals

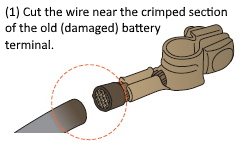

Step 3 Cut the Wire

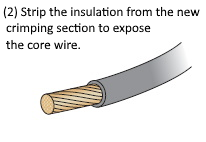

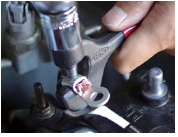

Step 4 Crimp the Terminal and Prepare

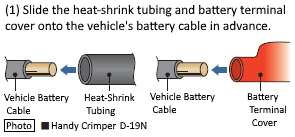

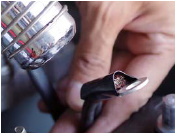

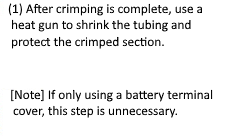

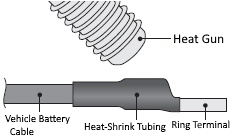

Step 5 Protect the Crimped Section with Heat-Shrink Tubing (Only if Using Heat-Shrink Tubing)

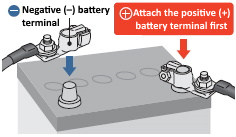

Step 6 Reattach the Battery Terminals

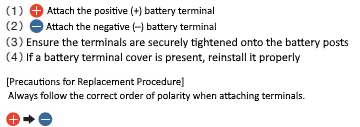

Quick Tip for Installing an Oxygen-Free Copper Battery Terminal onto a Lead-Acid Battery Post

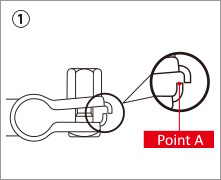

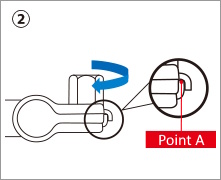

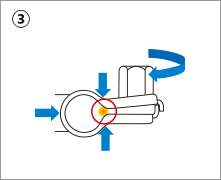

*The illustration above shows the bolt-type specification.

- Firmly insert the oxygen-free copper (OFC) battery terminal onto the post of the lead-acid battery.

- Tighten the M6 nut until Point A comes into contact with the opposite surface.

- By further tightening the M6 nut, Point A acts as a fulcrum, causing the oxygen-free copper battery terminal to clamp securely onto the post of the lead-acid battery.(The fulcrum effect ensures that the oxygen-free copper terminal is firmly and reliably fixed in place.)

- Immediately after installation, check for any looseness.

- Periodically inspect to confirm that the oxygen-free copper battery terminal remains securely tightened.

Battery Terminal FAQ

What is a battery terminal?

It is a component used to connect a vehicle, such as a car, to its battery (lead-acid battery). Battery terminals are attached to the “+ (positive)” and “− (negative)” posts of the battery to supply electricity to the vehicle’s entire electrical system.

What happens if the positive and negative terminals are connected incorrectly?

An incorrect connection can blow fuses and, in the worst case, damage electrical components or cause a fire due to wiring ignition. Always check the “+” and “−” markings on both the battery and the battery terminals before installation.

What happens if a battery terminal is loose?

Vibration while driving may cause poor contact, leading to engine failure to start, stalling, sudden electrical malfunctions, or a failure to recharge the battery. Always tighten the terminals securely and check regularly to ensure they are not loose.

There is white powder (sulfation) on the terminals. What should I do?

The white powder often seen on terminals is lead sulfate crystals or corrosion. If left untreated, it can cause poor contact or electrical conductivity issues. Clean with a brush or a dedicated cleaner, and check surrounding areas as needed.

Do I always need to remove the battery terminals when replacing a battery?

Yes. Always remove the negative terminal first, and when installing, connect the positive terminal first. Reversing the order can cause a short circuit, blown fuses, or sparks.

Note: If necessary, use a backup power device to preserve the vehicle’s memory functions before removing the terminals.

Are there differences in battery terminal materials?

Most are made of zinc alloy, but conductivity and corrosion resistance vary. At Hero Electric, some models use “oxygen-free copper,” which offers superior conductivity, reduced electrical resistance, and longer service life.

Is it safe to replace the terminals by myself (DIY)?

It is possible, but please check the vehicle manual or service guide first. Safety is critical—if a tool bridges the terminals, it may cause a dangerous short circuit. In modern vehicles, removing the battery may trigger warning lights, errors, or even prevent engine startup or driving.If you are uncertain, consult a repair shop or specialist.

Important notes:

Can battery terminals be reused?

Do not reuse terminals that are deformed or heavily corroded, as they may cause poor contact or damage. For safety, use new terminals. When replacing a battery, we recommend replacing the terminals at the same time.

| When installing the oxygen-free copper battery terminal,always check that there are no abnormalities on the post of the battery (lead-acid battery).Also, please make sure not to touch the battery fluid under any circumstances. |